At F2A, every installation is first and foremost a human and technical adventure.

Alongside our client MONDIAL FRIGO – IFC, we took on a major challenge: creating a refreshed, uniform, and comfortable working environment at the heart of the Sources ALMA mineral water bottling site.

To achieve this, the Texi Pulse solution proved to be particularly well suited.

Its diffusion slots help prevent direct drafts, create a comfort bubble in sensitive areas, and improve operators’ day-to-day working conditions.

Key figures of the project:

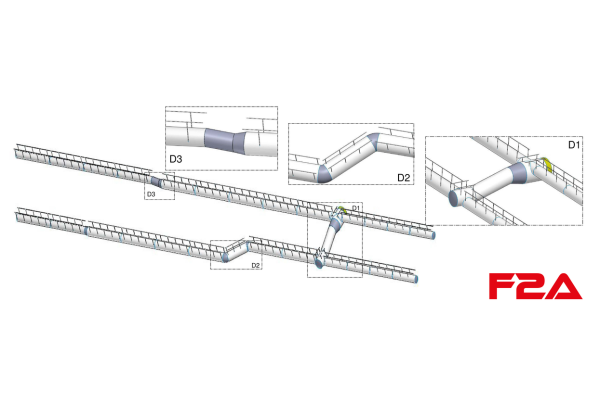

- A Ø1800 mm header

- 54,000 m³/h of air delivered into the network

- Over 100 linear meters of Texi Pulse textile ducting

- Controlled, comfortable air diffusion that does not interfere with the processes

But beyond the numbers, it is the added value of textile ducting that transformed the project:

- Comfort & air quality: thanks to the airflow orientation enabled by Texi Pulse, and the Coanda effect that guides the air precisely where needed

- Optimal hygiene: washable fabrics, antibacterial additives, constant control

- Modularity: perfectly adapted to the site’s constraints

- Lightweight & safety: quick installation, reduced physical effort

- Savings: simplified logistics, energy efficiency, and optimized installation

This installation once again illustrates our ability to design tailor-made solutions where technology truly serves people.

Congratulations to the F2A and MONDIAL FRIGO – IFC teams.